One of the major factors determining conveyor’s life span is the wear resistance qualities and it is the truest test of its value for money in the end. Generally, approximately 20% of surface wear is on the bottom cover, while 80% of conveyor belt surface wear occurs on the top cover of the belt.

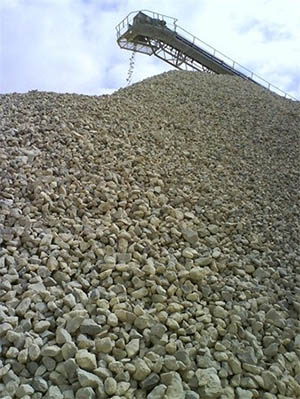

The abrasive action of the carried materials mainly cause the wear on the top cover. At some point, like the loading point where the belt is expected to shoulder the impact of the mass material and the discharge point where the material is effectively 'accelerated' by the belt surface, the abrasive action is increased.

The friction contact with the drum surface and idlers primarily cause the wear on the bottom cover of the belt . Many other factors such as misaligned or worn drums and idlers set at incorrect angles can adversely influence the rate and uniformity of this type of wear. The belt wear can be accelerated by factors such as an unclean environment where there is a build-up of waste material and an ozone penetration. Wear to the top cover surface can also be abraded due to belt cleaning systems, especially steel edged scrapers. However, increasing the thickness of the belt do not necessarily improve its life expectancy. The actual thickness of the cover is a critical consideration and specifying the right thickness can affect on operation. In principle, the maximum ratio of the thickness between the top cover and the bottom cover should not exceed three to one. In actual practice, the belt cover’s abrasion resistance quality is much more important than its thickness, while in theory, the shorter the conveyor and the more abrasive the material, the thicker the cover should be. However, many conveyor belt suppliers provide belts with covers thicker than they are actually needed, in an effort to make up for inadequate abrasion resistant qualities potentially causing other problems in operation. In actual fact, there are different types of abrasion resistant cover as there are a number of different causes of wear and abrasion because of the variety of materials carried on conveyor belts. For instance, materials such as aggregate, sand and gravel literally acting like sandpaper constantly scrubbing the rubber surface whereas heavy and sharp objects such as rocks can cause cutting and gouging of the belt cover.