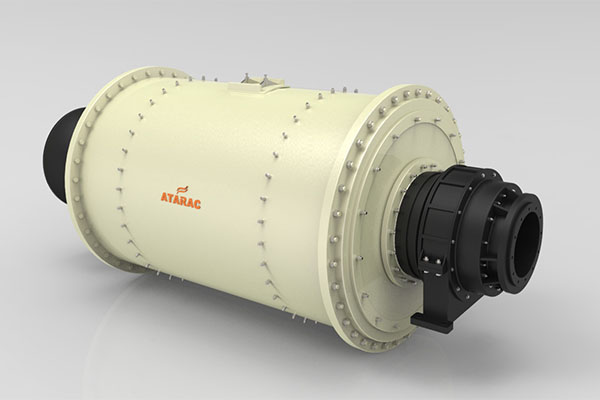

GMQG high-efficiency ball mill is composed of feeder, discharge opening, rotation part, transmission part (reducer, gear transmission shaft, motor and power control cabinet) and other main parts, which is widely used in black, non-ferrous metal mining, building materials, chemicals, electricity, coal, transportation, light industry and other industrial sectors. Lattice-type ball mill has lattice panels at the discharge end, with more volume of ball, larger installation power, higher capacity and more coarse discharge granularity and usually used in primary crushing; Spill-over ball mill are usually used in fine grinding without lattice panels at the end and with higher discharge opening, less volume of ball, smaller installation power, lower production capacity and finer discharge granularity.

| Model | Barrel size(mm) | Effective volume (m3) | Ball load (t) | Barrel rotating speed(r/min) | Power(kw) | Output size (㎜) |

Capacity (t/h) |

Weight (kg) |

Remark |

| Dia*length | |||||||||

| GMQG1530 | 1500×3000 | 4.0 | 8 | 27.6 | 75 | 0.8-0.074 | 12-2.8 | 15500 | 380V |

| GMQG1535 | 1500×3500 | 4.6 | 11 | 27.6 | 75-90 | 0.8-0.074 | 14-3.4 | 16300 | 380V |

| GMQG1830 | 1800×3000 | 6.5 | 13 | 25.3 | 132 | 0.8-0.074 | 21-4.8 | 28200 | 380V |

| GMQG1835 | 1800×3500 | 7.58 | 16 | 25.3 | 160 | 0.8-0.074 | 25-5.8 | 30800 | 380V |

| GMQG1840 | 1800×4000 | 8.65 | 17.3 | 25.3 | 185 | 0.8-0.074 | 28-6.6 | 33400 | 380V |

| GMQG1845 | 1800×4500 | 9.75 | 19.5 | 25.3 | 210 | 0.8-0.074 | 31-7.2 | 36200 | 380V |

| GMQG2122 | 2100×2200 | 6.7 | 14.7 | 23.8 | 160 | 0.8-0.074 | 24-5.3 | 43200 | 380V |

| GMQG2130 | 2100×3000 | 9.2 | 17 | 23.8 | 185 | 0.8-0.074 | 26-6.0 | 46800 | 380V |

| GMQG2136 | 2100×3600 | 11.0 | 19 | 23.8 | 210 | 0.8-0.074 | 29-6.5 | 49100 | 380V |

| GMQG2140 | 2100×4000 | 12.2 | 20.5 | 23.8 | 220 | 0.8-0.074 | 32-7.2 | 50200 | 380V |

| GMQG2145 | 2100×4500 | 13.8 | 22 | 23.8 | 250 | 0.8-0.074 | 36-8.1 | 51800 | 380V |

| GMQG2424 | 2400×2400 | 9.8 | 20 | 22.8 | 220 | 0.8-0.074 | 32-6.6 | 54800 | 380V |

| GMQG2430 | 2400×3000 | 12.2 | 25 | 22.8 | 250 | 0.8-0.074 | 38-7.5 | 57800 | 380V |

| GMQG2436 | 2400×3600 | 14.6 | 30 | 22.8 | 280 | 0.8-0.074 | 42-8.5 | 60800 | 380V |

| GMQG2440 | 2400×4000 | 16.2 | 33 | 22.8 | 355 | 0.8-0.074 | 47-9.5 | 63800 | 380V |

| GMQG2445 | 2400×4500 | 18.2 | 37 | 22.8 | 400 | 0.8-0.074 | 55-10.5 | 66300 | 380V |

| GMQG2721 | 2700×2100 | 10.7 | 24 | 21.7 | 280 | 3.0-0.074 | 84-8.5 | 66400 | 6-10KV |

| GMQG2727 | 2700×2700 | 13.8 | 29 | 21.7 | 315 | 3.0-0.074 | 105-9.0 | 71700 | 6-10KV |

| GMQG2730 | 2700×3000 | 15.3 | 32.5 | 21.7 | 355 | 3.0-0.074 | 120-10 | 77300 | 6-10KV |

| GMQG2736 | 2700×3600 | 18.4 | 39 | 21.7 | 400 | 3.0-0.074 | 145-12 | 82400 | 6-10KV |

| GMQG2740 | 2700×4000 | 20.5 | 43 | 21.7 | 450 | 3.0-0.074 | 159-13 | 84730 | 6-10KV |

| GMQG2745 | 2700×4500 | 23.0 | 50 | 21.7 | 500 | 3.0-0.074 | 180-15 | 89100 | 6-10KV |

| GMQG3231 | 3200×3100 | 22.65 | 46.9 | 18.6 | 500 | 3.0-0.074 | 182-16 | 139000 | 6-10KV |

| GMQG3236 | 3200×3600 | 26.20 | 52 | 18.6 | 560 | 3.0-0.074 | 190-19 | 143000 | 6-10KV |

| GMQG3240 | 3200×4000 | 29.2 | 57 | 18.6 | 630 | 3.0-0.074 | 210-22 | 147000 | 6-10KV |

| GMQG3245 | 3200×4500 | 32.8 | 65 | 18.6 | 710-800 | 3.0-0.074 | 235-29 | 151000 | 6-10KV |

| GMQG3254 | 3200×5400 | 39.2 | 81.6 | 18.6 | 800-1000 | 3.0-0.074 | 280-35 | 161000 | 6-10KV |

| GMQG3640 | 3600×4000 | 35.6 | 75 | 17.3 | 800 | 3.0-0.074 | 230-25 | 185000 | 6-10KV |

| GMQG3645 | 3600×4500 | 40.8 | 88 | 17.3 | 1000 | 3.0-0.074 | 259-29 | 190000 | 6-10KV |

| GMQG3650 | 3600×5000 | 45.3 | 96 | 17.3 | 1120 | 3.0-0.074 | 288-35 | 200000 | 6-10KV |

| GMQG3660 | 3600×6000 | 54.4 | 117 | 17.3 | 1250-1500 | 3.0-0.074 | 310-38 | 220000 | 6-10KV |

| GMQG3685 | 3600×8500 | 79.0 | 144 | 17.3 | 1800 | 3.0-0.074 | 450-50 | 260000 | 6-10KV |

Wet spill-over type rolling bearing ball mill

| Model | Barrel size(mm) | Effective volume(m3) | Ball load(t) | Barrel rotating speed(r/min) | Power(kw) | Output size (㎜) |

Capacity (t/h) |

Weight (kg) |

Remark |

| Dia*length | |||||||||

| GMQY1530 | 1500×3000 | 4.0 | 8.4 | 27.6 | 75 | 0.8-0.074 | 11-2.6 | 15.1 | 380V |

| GMQY1535 | 1500×3500 | 4.6 | 10 | 27.6 | 75-90 | 0.8-0.074 | 13.2-3.0 | 16.0 | 380V |

| GMQY1830 | 1800×3000 | 6.5 | 12 | 25.3 | 110-132 | 0.8-0.074 | 20-4.5 | 27.8 | 380V |

| GMQY1835 | 1800×3500 | 7.58 | 15 | 25.3 | 132-160 | 0.8-0.074 | 23-5.0 | 29.7 | 380V |

| GMQY1840 | 1800×4000 | 8.65 | 16 | 25.3 | 160-185 | 0.8-0.074 | 25-6.0 | 32.6 | 380V |

| GMQY1845 | 1800×4500 | 9.75 | 18 | 25.3 | 185-210 | 0.8-0.074 | 28-6.8 | 35.5 | 380V |

| GMQY2122 | 2100×2200 | 6.7 | 14.7 | 23.8 | 160 | 0.8-0.074 | 22-5.0 | 42.9 | 380V |

| GMQY2130 | 2100×3000 | 9.2 | 17 | 23.8 | 185 | 0.8-0.074 | 25-5.8 | 46.5 | 380V |

| GMQY2136 | 2100×3600 | 11 | 19 | 23.8 | 210 | 0.8-0.074 | 28-6.0 | 48.0 | 380V |

| GMQY2140 | 2100×4000 | 12.2 | 20.5 | 23.8 | 220 | 0.8-0.074 | 30-7.0 | 49.9 | 380V |

| GMQY2145 | 2100×4500 | 13.8 | 22 | 23.8 | 250 | 0.8-0.074 | 34-8.0 | 51.3 | 380V |

| GMQY2424 | 2400×2400 | 9.8 | 18.8 | 22.8 | 210 | 0.8-0.074 | 30-6.2 | 54.0 | 380V |

| GMQY2430 | 2400×3000 | 12.2 | 23 | 22.8 | 250 | 0.8-0.074 | 34-6.6 | 57.0 | 380V |

| GMQY2436 | 2400×3600 | 14.6 | 25 | 22.8 | 280 | 0.8-0.074 | 40.5-7.9 | 59.68 | 380V |

| GMQY2440 | 2400×4000 | 16.2 | 28 | 22.8 | 315 | 0.8-0.074 | 45-8.7 | 62.9 | 380V |

| GMQY2445 | 2400×4500 | 18.2 | 31 | 22.8 | 355 | 0.8-0.074 | 50-9.8 | 65.5 | 380V |

| GMQY2721 | 2700×2100 | 10.7 | 20 | 21.7 | 280 | 3.0-0.074 | 76-6.0 | 63.5 | 6-10KV |

| GMQY2727 | 2700×2700 | 13.8 | 25.5 | 21.7 | 315 | 3.0-0.074 | 98-7.8 | 66.7 | 6-10KV |

| GMQY2730 | 2700×3000 | 15.3 | 28.0 | 21.7 | 355 | 3.0-0.074 | 108-8.8 | 75.6 | 6-10KV |

| GMQY2736 | 2700×3600 | 18.4 | 34 | 21.7 | 355-400 | 3.0-0.074 | 130-10.5 | 81.8 | 6-10KV |

| GMQY2740 | 2700×4000 | 20.5 | 37 | 21.7 | 400-450 | 3.0-0.074 | 144-11.5 | 83.5 | 6-10KV |

| GMQY2745 | 2700×4500 | 23.0 | 42.5 | 21.7 | 500 | 3.0-0.074 | 180-13 | 87.6 | 6-10KV |

| GMQY3231 | 3200×3100 | 22.65 | 22.65 | 18.6 | 450 | 3.0-0.074 | 164-14.4 | 127 | 6-10KV |

| GMQY3236 | 3200×3600 | 26.20 | 26.2 | 18.6 | 500 | 3.0-0.074 | 171-17.1 | 131.0 | 6-10KV |

| GMQY3240 | 3200×4000 | 29.2 | 29.2 | 18.6 | 560 | 3.0-0.074 | 190-20 | 135.0 | 6-10KV |

| GMQY3245 | 3200×4500 | 32.8 | 61.0 | 18.6 | 630 | 3.0-0.074 | 228-22 | 139.0 | 6-10KV |

| GMQY3254 | 3200×5400 | 39.3 | 73.0 | 18.6 | 710 | 3.0-0.074 | 270-26 | 148.7 | 6-10KV |

| GMQY3640 | 3600×4000 | 35.6 | 67 | 17.3 | 710 | 3.0-0.074 | 210-20 | 165 | 6-10KV |

| GMQY3645 | 3600×4500 | 40.8 | 76 | 17.3 | 800-1000 | 3.0-0.074 | 233-26 | 170 | 6-10KV |

| GMQY3650 | 3600×5000 | 45.3 | 86 | 17.3 | 1120 | 3.0-0.074 | 260-31.5 | 180 | 6-10KV |

| GMQY3660 | 3600×6000 | 54.4 | 102 | 17.3 | 1250 | 3.0-0.074 | 280-34 | 200 | 6-10KV |

| GMQY3685 | 3600×8500 | 79.0 | 131 | 17.3 | 1500 | 3.0-0.074 | 400-45 | 240 | 6-10KV |

Please Feel free to give your inquiry in the form below.We will reply you in 24 hours.