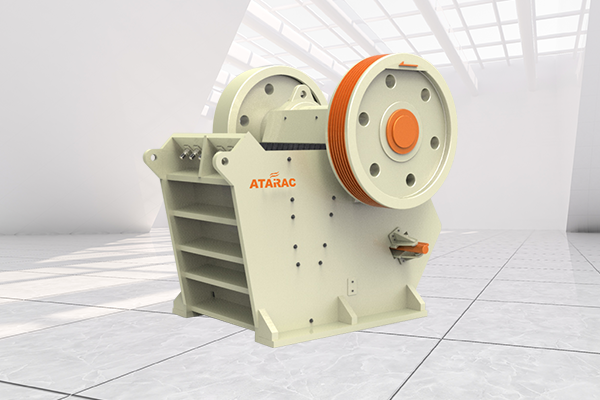

C series jaw crusher

Max. Feed Size: 680-1200 (mm)

Processing Capacity: 185-1300 (t/h)

Application Fields: metallurgy, mining, chemical, cement, construction, etc

Applied Material: limestone, dolomite, phosphate ore.

Tel.: (86)-021-38226566 E-Mail: [email protected]

Description

C series Jaw Crusher is a new kind of product that our company manufactured by cooperating with the technology of ALTAIRAC France. It is a jaw crusher with high throughput, low energy consumption, reliable structure and easy maintenance which is a preferred primary crusher for various rocks.

Features

- High-strength design ensures long life time of frame.

- The whole set of heavy type movable jaw is durable. The swing jaw plate integrates high-quality casting steel structure, optimized swing jaw through finite element analysis, forged heavy eccentric shaft, high quality large type self-aligning rolling bearing of heavy loading and the large type casting fly wheel. These designs assure the stroke resistance and stability of the movable jaw integrates.

- Symmetrical V type cavity. Compared with traditional jaw crusher, the processing capacity is increased by 20%, power consumption is reduced by 10%-15%.

- Adopts optimized four-bar linkage, the machine possesses higher rotate speed, longer stroke, better running, so as to maximize its efficiency.

- By adopting kinematics simulation analysis to achieve dynamic equilibrium, the machine runs stably with small vibration.

- The adjustable transmission angle provides more output under the condition of the same discharge opening compared with other type of similar machines.

- One piece of steel-cast bearing seat.

- The hydraulic jack system to adjust discharge opening. As the shims are added or reduced from side, which is easier, safer, more convenient, and reduce the down time compared with traditional jaw crusher.

- Unique lubrication system.

- High utilization of jaw plate, less consumption of materials and power.

Working Principle

Electrical motor drives the belt wheel to make the swing jaw move following the specific track by eccentric shaft. After the materials enter into the crushing chamber, they are crushed between the two jaw plates by impacting, bending, and striking, and then discharged from the discharge opening.

Technical Specification

| Model | Input Opening (mm) | Discharge Opening(mm) | Capacity(t/h) | Power (kw) |

| C0402 | 400×250 | 20-80 | 7-23 | 15 |

| C0604 | 600×400 | 400-100 | 25-64 | 30 |

| C0705 | 750×500 | 50-120 | 60-120 | 55 |

| C0906 | 960×630 | 50-150 | 125-290 | 90 |

| C1204 | 1200×400 | 20-90 | 18-80 | 55 |

| C1303 | 1300×400 | 20-90 | 18-110 | 75 |

| C1008 | 1020×800 | 65—250 | 185-500 | 110 |

| C1210 | 1160×1050 | 75-275 | 270-810 | 132 |

| C1412 | 1400×1200 | 95-300 | 390-950 | 185 |

| C1615 | 1610×1400 | 115-300 | 470-1150 | 220 |

| C1815 | 1800×1500 | 115-325 | 630-1300 | 355 |

Remark:

1.The capacity listed in the table is the corresponding parameters when crushing rocks with the bulk density of 1.6t/m³;

2.The throughput capacity may different when the material is different.