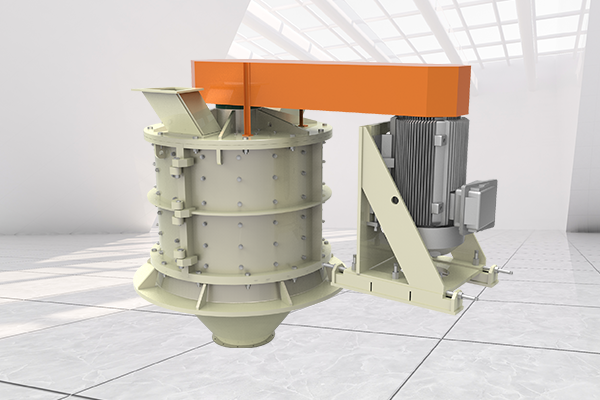

PFL Vertical Complex Crusher

Max. Feed Size: 680-1200 (mm)

Processing Capacity: 185-1300 (t/h)

Application Fields: metallurgy, mining, chemical, cement, construction, etc

Applied Material: limestone, dolomite, phosphate ore.

Tel.: (86)-021-38226566 E-Mail: [email protected]

Description

PFL Series Vertical Complex Crusher is developed by our company which based on absorbing the international advanced technology and applying company’s decades practical experience. It is optimized to be a new type fine crushing, coarse grinding crusher, which apply the crushing mechanism of impact and grinding at the same time. PFL vertical complex crusher is ideal equipment for fine crushing in cement plant, which can realize more crushing and less grinding, decrease the consumption of the energy. It is widely used for crushing cement raw material and clinker, also can be widely used for solvents and raw materials fine crushing in metallurgical industry and various hard mineral crushing processing in other construction, building materials, chemical industry and some other fields.

Features

1. Simple structure, high throughput, high crushing ratio, high rate of final product, low energy consumption.

2. The hammer and liner apply wear resistant complex alloy material, which is of high hardness and high toughness. So the service life of them is long.

3. Good sealing performance, little dust pollution, low noise, stable running, convenient operation and maintenance.

4. According to the needs of customers, the main gear can be designed at the top of the machine or at the bottom.

Working Principle

Electrical motor drives the belt wheel to make the swing jaw move following the specific track by eccentric shaft. After the materials enter into the crushing chamber, they are crushed between the two jaw plates by impacting, bending, and striking, and then discharged from the discharge opening.

Technical Specification

| Model |

Max. Feed Size (mm) |

Discharge Size (mm) |

Rotating Speed (r/min) |

Capacity (t/h) |

Power (kw) |

| PFL-750Ⅲ | ≤100 | ≤3,70-90% | 800~1350 | 8~20 | 45 |

| PFL-1000Ⅲ | ≤120 | ≤3,70-90% | 650~980 | 15~30 | 55 |

| PFL-1250Ⅲ | ≤150 | ≤3,70-90% | 510~770 | 35~45 | 90 |

| PFL-1500Ⅲ(Ⅱ Ⅸ) | ≤180 | ≤3,70-90% | 430~640 | 50~70 | 132 |

| PFL-1750Ⅲ(Ⅱ Ⅸ) | ≤200 | ≤3,70-90% | 420~540 | 70~100 | 160 |

| PFL-2000Ⅲ | ≤220 | ≤3,70-90% | 360~540 | 90~120 | 200 |

| PFL-2300Ⅲ | ≤240 | ≤3,70-90% | 330~450 | 120~160 | 250 |

Remark:

1.The capacity listed in the table is the corresponding parameters when crushing rocks with the bulk density of 1.6t/m³;

2.The throughput capacity may different when the material is different.