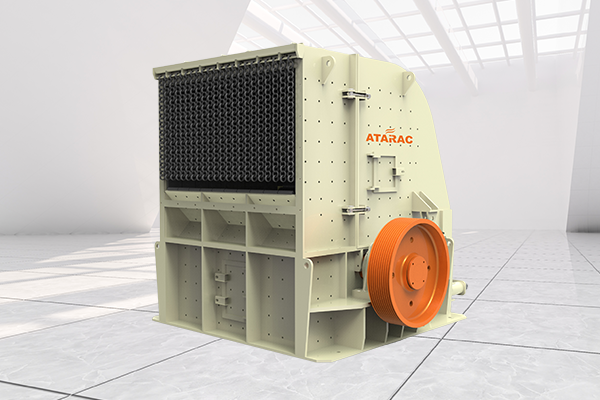

PFS Series Vortex Strong Impact Crusher

Discharge granularity: 25-50 (mm) [80-90%]

Processing Capacity: 46-670 (t/h)

Application Fields: cement, construction, chemistry, highway and railway.

Applied Materials: basalt, andesite, cobble, granite.

Tel.: (86)-021-38226566 E-Mail: [email protected]

Description

PFQ Impact Crusher is a newly developed series impact crusher with high efficiency. It has smart structure and can be applied to primary crushing, secondary and fine crushing of a variety of materials with compression strength less than 250Mpa. PFQ impact crusher can be widely used for sand and aggregate processing in water conservancy and hydropower projects and other infrastructure constructions, such as highway, high-speed rail, building materials, mining and urban construction waste treatment.

Features

- Specially designed three crushing chambers, which improves the production capacity of PFQ impact crusher, makes the feed size bigger and the product shape better.

- The optimally designed rotor provides powerful rotational inertia and strong impact force of hammer head, which improves the productivity and increases the crushing ratio.

- Specially designed anti-wear alloy C shape hammer keeps the shape of impact face in product life cycle. It ensures that the product shape and particle size distribution is very stable.

- Standard modular designed liner and tooth impact plate of PFQ impact crusher have common-ability and interchangeability, which improve the utilization ratio and prolong the service life of PFQ impact crusher.

- Special hammer fitting structure improves hammers’ stability and convenient dismounting, it also greatly improve the work efficiency.

- The discharging opening size of the machine can be adjusted according to the requirement of product size and particle size distribution.

- The standard hydraulic lifting device will be provided with the machine. It is optional to supply special lifting tools for replacing hammers, which is flexible and can be easily maintained.

Working Principle

Electrical motor drives the belt wheel to make the swing jaw move following the specific track by eccentric shaft. After the materials enter into the crushing chamber, they are crushed between the two jaw plates by impacting, bending, and striking, and then discharged from the discharge opening.

Technical Specification

| Model | Max. Feed Size(mm) |

Discharge Size (mm) |

Capacity (t/h) |

Power (kw) |

|

| <150MPa | <250MPa | ||||

| PFQ1108 | 300 | 150 | 30 | 50~100 | 75 |

| PFQ1110 | 400 | 200 | 35 | 80~150 | 110 |

| PFQ1310 | 400 | 200 | 40 | 140~200 | 160 |

| PFQ1313 | 400 | 250 | 40 | 180~260 | 200 |

| PFQ1315 | 400 | 300 | 40 | 200~300 | 250 |

| PFQ1320 | 400 | 300 | 40 | 300~400 | 2×160 |

| PFQ1520 | 500 | 400 | 40 | 350~550 | 2×250 |

| PFQ1623 | 700 | 400 | 40 | 600~780 | 2×355 |

| PFQ1823 | 700 | 400 | 40 | 650~1000 | 2×400 |

Remark:

1.The capacity listed in the table is the corresponding parameters when crushing rocks with the bulk density of 1.6t/m³;

2.The throughput capacity may different when the material is different.