Description

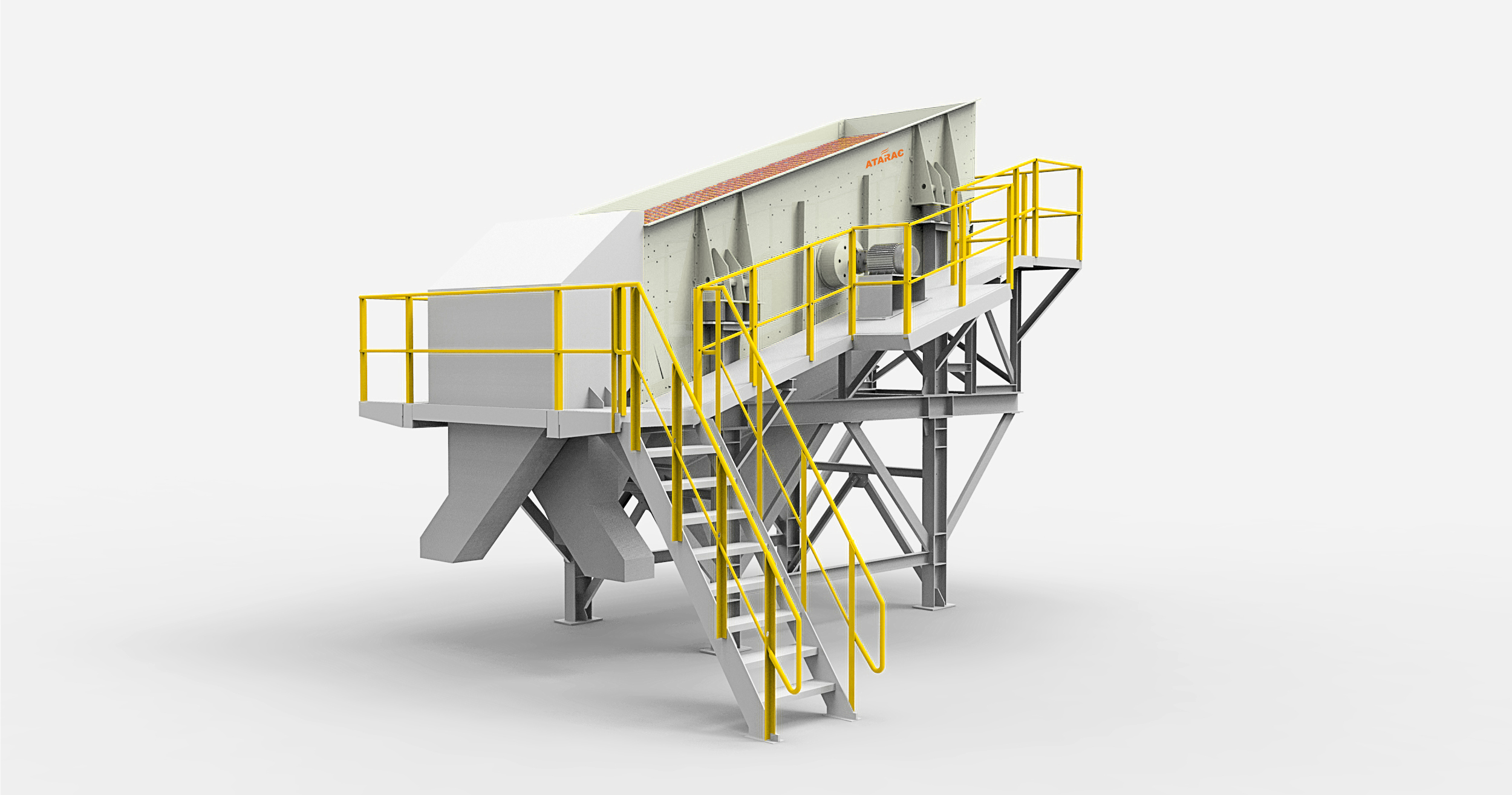

The modular crushing and screening plant is consisting of one or several crushing or screening units based on the customers’ needs of the projects.

Features

- It is mainly used for screening and classifying of the materials in the primary and secondary crushing stage.

- Smart structure and good locking: all independent workpiece can be disassembled, which is convenient for assembly and transportation.

- The slide type discharging chute is designed in front of the Vibrating Screen, which is easy for the maintenance.

- Designed discharging chute in the under of Vibrating Screen, which is easy for assembling, disassembling and transportation.

- The ladder, handrail and surrounding type of walkways will be designed and facilitated for the screening plant, which is convenient to do the inspection and maintenance for any part of the Vibrating Screen.

Technical Specification

| Model | MS-2160 | MS-2460 | MS-2475 | MS-2773 | MS-3060 | MS-3073 | MS-3673 | |

| Max.feeding size(mm) | 200 | 200 | 200 | 200 | 200 | 200 | 200 | |

| Capacity(t/h) | 115-820 | 120-880 | 150-950 | 150-1100 | 150-900 | 150-1200 | 220-1500 | |

| Layers | 2/3/4 | 1/2/3 | 2/3 | 2/3 | 2/3 | 2/3 | 2/3 | |

| Power(kw) | 30/37/45 | 30/37/45 | 45/55 | 55 | 45/55 | 55/2*37 | 2*37/2*45 | |

| The standard configuration | Model | YKR2160 | YKR2460 | YKR2475 | YKR2773 | YKR3060 | YKR3073 | YKR3673 |

| Discharging chute | √ | √ | √ | √ | √ | √ | √ | |

| Fine discharging chute | √ | √ | √ | √ | √ | √ | √ | |

| Platform | √ | √ | √ | √ | √ | √ | √ | |

| Supporting module | √ | √ | √ | √ | √ | √ | √ | |

| Ladder and handrail | √ | √ | √ | √ | √ | √ | √ | |