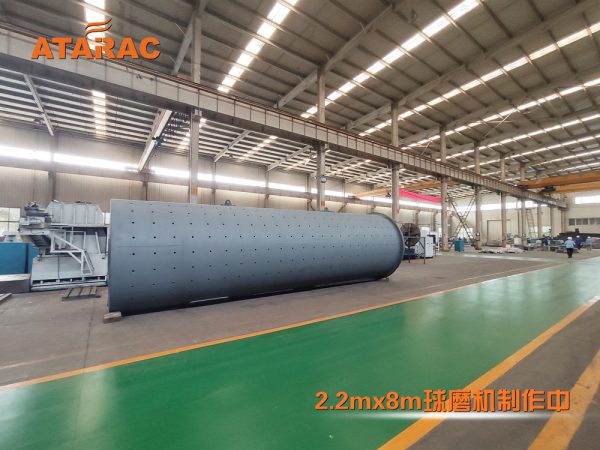

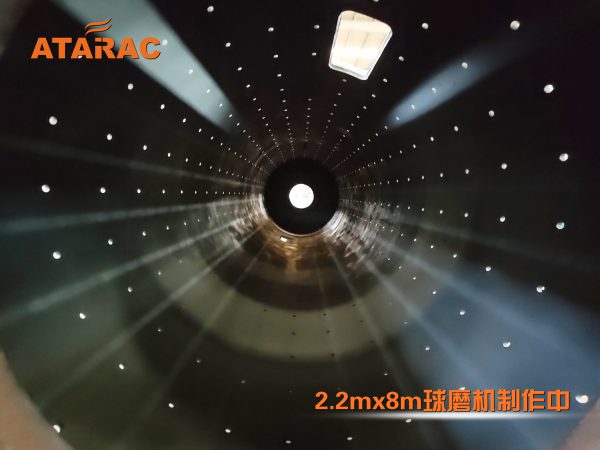

A 2.2x8m ball mill is being processed in the Ateric workshop.

The ball mill is supported by rolling bearing instead of sliding bearing bearing. Compared with sliding bearing bearing, it can save 10 ~ 20% energy. Under the same power condition, the production capacity can be increased by 10 ~ 20%. Using dry oil grease instead of thin oil lubrication station, high efficiency and energy saving ball mill does not need to be equipped with high price of low pressure lubrication station, reduce one-time investment cost. Diameter Φ2700mm above the mine ball mill can use high pressure motor, pneumatic clutch, big gear dry oil spray lubrication and slow driving device, for turning, maintenance use. Users can choose according to their needs.

The ball mill is a horizontal cylinder rotating device with outer gear drive. The material is uniformly entered into the mill by the feeding device through the spiral of the feeding hollow shaft. There is corrugated lining plate in the warehouse and steel balls of different specifications inside. The centrifugal force generated by the rotation of the cylinder will bring the steel balls to a certain height and then fall down, which will have the impact and grinding effect on the material.

Application: High efficiency and energy saving ball mill is widely used in black and non-ferrous metal mines, non-metal mines, building materials, chemical industry, electric power, coal, transportation, light industry and other industrial sectors.

Material: high efficiency and energy saving ball mill grinding all kinds of ore, rock and artificial sand and other materials.